As we all know, Terminal Block is a kind of connector. In the electric power automation connection system, the appearance of Terminal Block can be said to free the hands of maintenance personnel. The terminal block has the advantages of simple structure, various types and flexible application. Especially when the terminal failure, the replacement is very simple, only need to immediately remove the bad terminal replacement of the same model specifications of the new terminal can be, greatly reducing the maintenance time. The connection way of the terminal block is generally divided into five kinds. Here is to explain it carefully.

[ Screw connection ]

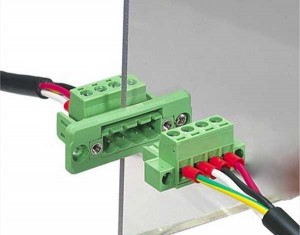

Screw connection is the connection method of screw type terminal block. It is suggested that you should pay attention to the maximum and minimum cross section of the allowed connecting wire and the maximum twisting strength of the screws with different specifications.

[ Welding ]

The most common type of welding is nail welding. The most important thing in the soldering connection is the continuity of the metal between the soldering material and the welding surface. So for the terminal block, the cold pressed terminal, the key is solderability. The most common coatings on the soldered ends of ring terminals are tin, silver, and gold. The reed contact pair has the welding type, the punching eye welding type and the notched welding type: the pinhole contact pair has the drilling arc notched type at the welding end.

[ Pressure ]

Clamping is a technique used to shrink and deflect a metal material to a desired extent and to connect a wire to a contact pair. Good crimping connection can cause metal materials to melt each other flow, so that the wire and contact on the raw material symmetrical deformation. This kind of connection is similar to the cold welding connection, both can obtain good mechanical strength and electrical continuity, it can withstand more harsh environment and requirements. At this stage, it is widely believed that the appropriate crimping connection is better than tin welding, especially in large current flow places must be used crimping link. When pressing, special pressing pliers or automatic or semi-automatic pressing machine should be selected. Should be based on the cold pressed terminal, cold pressed terminal wire section, the appropriate use of contact to the wire tube. Note that the crimping connection is a permanent connection, so it can only be used once.

[ wire wrap ]

Wound wire is directly coiled on the angular contact wound column. When the wire is wound, the wire is wound under the condition that the tension is controlled, and pressed into and fixed at the edges and corners of the wound column of the contact part, so as to form air-tight contact. There are several provisions for the wound wire: the nominal diameter of the wire should be within the range of 0. 25mm~1. When the diameter of conductor is not more than 0.5 mm, the tensile strength of conductor material is not less than 15 %; The tensile strength of the conductor material shall not be less than 20% when the diameter of the conductor is more than 0.5 mm. The winding tools include a winding gun and a stationary winding machine.

[ Pierce the connection ]

Piped connection is called insulation displacement connection, is invented by the United States in the 1960s a new technology, with high credibility, low cost, convenient to use and other characteristics, has been widely used in a variety of printed board terminal blocks, cold pressing terminals, ring terminals. It is suitable for the connection of ribbon cable. When connecting, the cable sheath of the cable is not stripped off, but the sharp end of the “U” shape of the terminal that contacts the reed is pierked into the cable sheath, so that the conductor of the cable slowly enters the groove that contacts the reed and is clamped, thus producing inseparable electrical connection between the conductor of the cable and the terminal reed. It requires only simple tools, but requires a cable with a prescribed wire gauge.

Post time: Apr-21-2021