Flexible printed circuit board, FPC connector scientific name is popular to speak is to use soft material made of (material) can be folded, bent, FPC connector products is used to connect to circuit board (PCB) and the flexible printed circuit board (FPC), realization of mechanical and electrical connection effect, has flexibility, folding, the advantages of the light weight, thin thickness, therefore widely used in consumer electronics and automobile electronics etc.

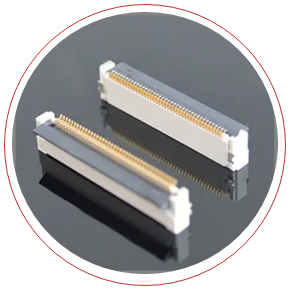

FPC connector can achieve thin, and in order to reduce the occupant area of the connector, and to seek miniaturization, high frequency signal transmission connector, this connector contains four parts, namely rubber core, tongue piece, terminal, welding piece. With the development of small and thin devices, some devices will choose FPC to replace the traditional wiring harness, and some connectors will be replaced at the same time.

Advantages of FPC:

1.FPC flexible circuit can twist, bend, fold, can improve the space utilization and flexibility of products, and meet the development needs of electronic products tend to miniaturization, high density.

2.FPC can move and expand freely in three-dimensional space to achieve integration of component assembly and wire connection, which is beneficial to reduce the volume and weight of electronic products, reduce assembly procedures to a certain extent and enhance reliability.

3. FPC can withstand millions of times of dynamic bending, can be well used in the internal connection system of the product, become an indispensable part of the product function. FPC can realize small, light and thin in one, can provide excellent electrical performance, fast transmission of electrical signals, so that the product components run well.

With the development of lightweight, miniaturization and folding of today’s terminal equipment, the consumption of internal FPC in various electronic devices is increasing due to the consideration of lightweight. The flexible nature of the FPC reduces the total number of connections required, which means fewer solder joints, connectors, and contact crimps, replacing some traditional wiring harnesses and connectors to a certain extent.

Take automobiles as an example. With the electrification and intelligence of automobiles, FPC has gradually become the new favorite of the automobile industry. On the one hand, traditional LVDS wiring harnesses, such as traditional wiring process, are complicated and cost is relatively high. On the other hand, in order to reduce the weight of the whole vehicle, car companies will choose to replace most wiring harnesses with FPC.

At the same time, in the smaller space, the FPC may also replace part of the connector, connector applications may be reduced. However, connectors still have irreplaceable advantages, and only using FPC to connect also has certain disadvantages. For example, if there is no connector to connect, the method of welding will be used, and the cost of welding will be higher than that of using two connectors. Secondly, because the FPC is connected by welding in the early stage, it is very inconvenient when the fault needs to be repaired in the later stage.

Although the replacement of wired components through FPC can eliminate redundant wiring work, save more space and cost. But in practice, FPC can have synergies with connectors. For example, in the mobile phone module, the connector can be attached to the FPC to drive more applications of the connector.

In general, at a high level of integration, some connectors will inevitably be replaced, but the overall demand for connectors is still on the rise. Especially in the trend of intelligence, more and more modules in the equipment, the demand for connectors will be more and more large. At the same time, the technology of connectors is constantly updated and iterated to adapt to the ever-evolving application scenarios.

Post time: Apr-07-2021