2+1+7 IPX5 Industrial Connector for AGV/CNC/EV Chargers/Robotics/Warehouse Automation

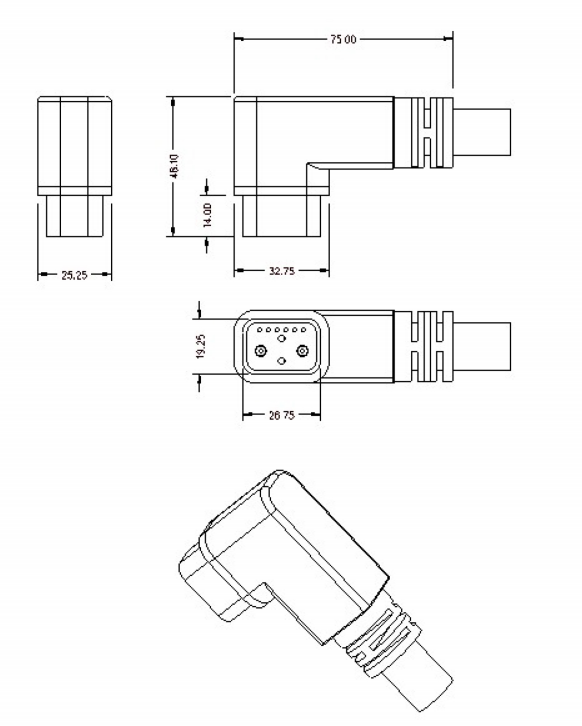

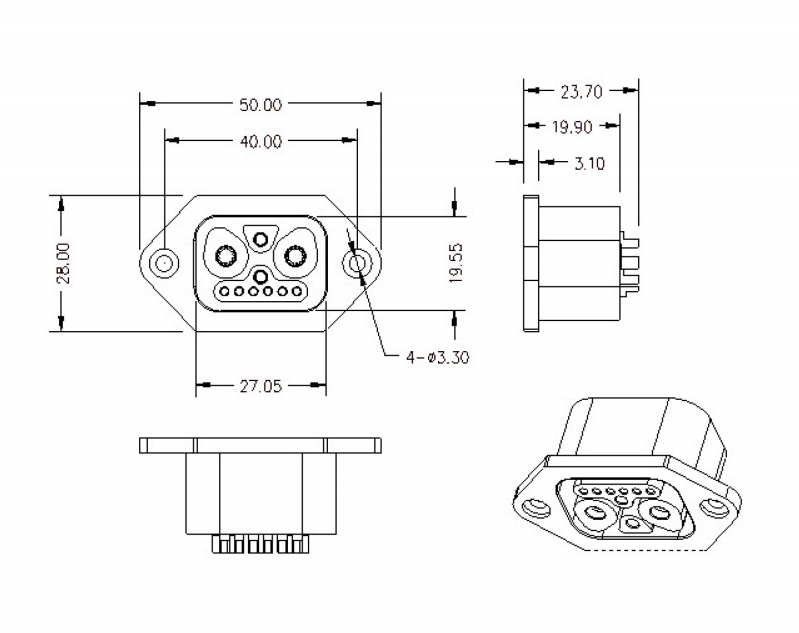

PRODUCT DRAWING

PLUG

SOCKET

Testing & Acceptance

Basic Performance Tests

| No. | Test Item | Method | Requirement | Notes |

| 1 | Contact resistance | 4-wire | ≤1.5 mΩ | For +/- only |

| 2 | Insulation resistance | 500V DC | ≥10MΩ min | |

| 3 | Dielectric strength | 1500V AC | No breakdown between +/- | For +/- only |

| 4 | Terminal temperature rise | 25℃ ambient, 50A for 1h | ΔT≤50°C | For 6mm² cable |

| 5 | Insertion/extraction force | 150mm/min mating speed | >30N | |

| 6 | Solder strength | Pull test | Main cable≥70N, signal≥30N | |

| 7 | IP rating | Water spray test | IPX5 (Mated condition |

Environmental Reliability Tests

| No. | Test Item | Method | Requirement | Notes |

| 1 | Damp heat test | 85℃±2℃, 90-95% RH, 24h → 2h recovery | No visual/functional degradation | |

| 2 | Thermal shock | -10℃↔85℃, 5 cycles (30min transition) | No visual/functional degradation | |

| 3 | High temp. test | 85℃±2℃, 24h | No visual/functional degradation | |

| 4 | Low temp. test | -10℃±2℃, 24h | No visual/functional degradation | |

| 5 | Salt spray test | NSS 48h | No corrosion, smooth mating |

Mechanical Reliability Tests

| No. | Test Item | Method | Requirement | Notes |

| 1 | Mating cycles | 3000 cycles,150mm/min | Conductivity OK after 5000 cycles | |

| 2 | Screw durability | 10N·m (Torque), 8 cycles | Thread integrity maintained | Electric screwdriver required |

| 3 | Flex test | ±45°, 1500 cycles | No disconnection/debonding | |

| 4 | Drop test | -10℃±2℃, 24h | No damage |

Write your message here and send it to us